Braised products are one of the indispensable foods in our lives. At present, manufacturers of braised products often have various problems during the processing, such as the inability to intelligently control temperature in the old-fashioned production process of braised products. , The product cannot be put in and out of the pot as a whole, the product damage rate is too high, the old soup cannot automatically enter and leave the sauce pot, the oil generated on the surface of the sauce pot cannot be automatically collected, the old soup and products cannot be automatically and quickly cooled, the steam water cannot be recycled, the waste of the sauce, the sauce After the product is out of the pan, it is difficult to automate the turnover aseptically, and to intelligently monitor every production process.

In response to these “old problems” in the stewed cooking industry, Qingdao Ruizhi Intelligent Equipment Technology Co., Ltd. has established a strong partnership with well-known national companies and well-known brands such as Dezhou Braised Chicken, Daokou Roasted Chicken, Henan Zangying Bridge, Juewei Duck Neck, etc. Cooperation, customized and produced a complete set of fully automatic intelligent brine boiling assembly line for them, and has been put into production, and achieved great success.

The brine boiling pot and the fully automatic intelligent brine boiling assembly line can realize the full automation of the production process, solve the intelligent temperature control in the production process of the sauce and brine products, and the basket-type overall in and out of the pan, breaking through the technological difficulties of zero product damage, and solving the problem at the same time. In the braising process, automatic access to the old soup, automatic oil skimming, automatic cooling of the old soup, and steam water recovery in the stewed cooking industry are urgently needed to solve the problems in the stewed cooking industry; the industry difficulties in the automatic turnover and intelligent monitoring of each production process of the sauce and stewed products cannot be aseptic All have been well resolved.

With the development of the times of living standards, people's living standards have become more and more abundant. It is precisely in this way that people's pursuit of food is also very demanding. Not only do foods require a series of pursuits such as deliciousness, taste, color, etc., so now there are more and more manufacturers using mechanized and intelligent equipment.

Fully automatic intelligent brine boiling line has a wide range of uses

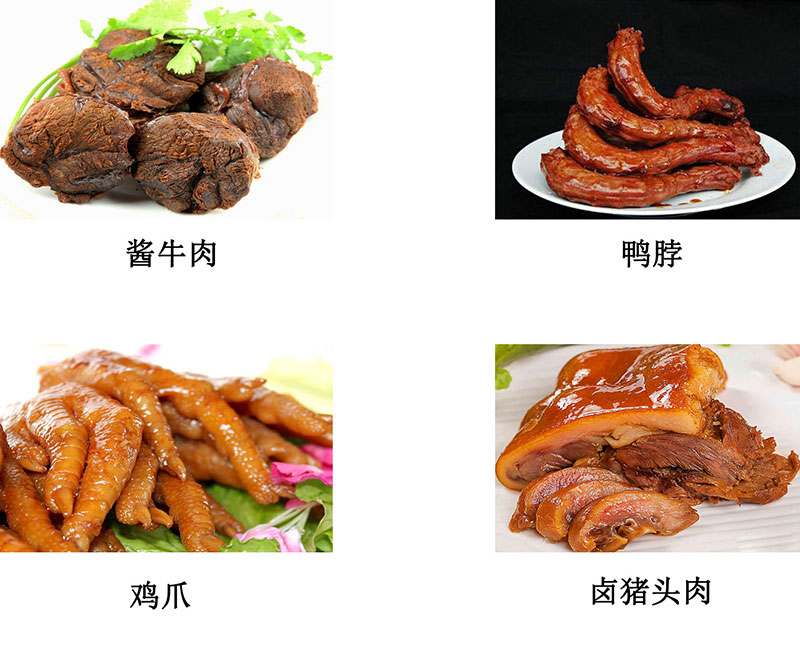

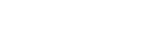

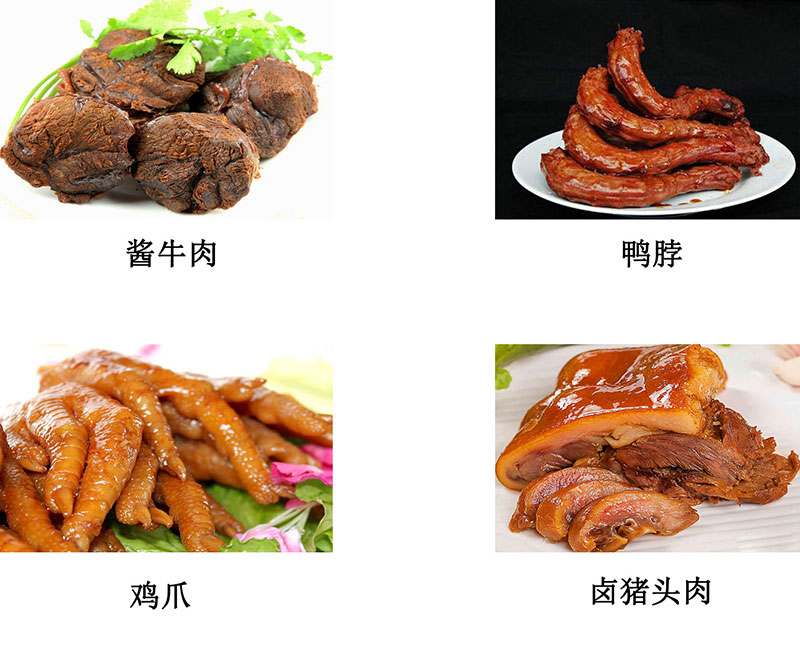

Widely used in grilled chicken, roasted chicken, smoked chicken, duck by-products (duck neck, duck wings, duck head, duck gizzards, duck collarbone, duck feet, duck legs, duck tongue, duck intestines), braised pig heads and trotters, pork Processing and production of various sauced and stewed products such as beef products, donkey meat products, canned products, etc.

Braised boiling pot, automatic intelligent braised boiling assembly line

All are made of food grade 316 stainless steel, which can meet the different needs of different customers. The size specifications and equipment functions can be customized according to actual needs. The halogen boiling pot and the automatic intelligent brine boiling assembly line can be divided into electric heating, steam heating, and heat transfer oil heating. For heating methods, the equipment can be equipped with an automatic temperature control device, which can effectively control the temperature and cooking time in the pot. It is equipped with an inner basket. The product is placed in the inner basket for cooking, which is hygienic and clean, easy to operate, and can be lifted in a single basket. The outer wall of the pot takes away the thermal insulation layer, which effectively prevents the dissipation of heat and saves energy.

The main structure of the brine boiling pot and the automatic intelligent brine boiling assembly line

The most important part of the brine boiling pot, the automatic intelligent brine boiling assembly line, is a square brine boiling pan made of 316 material, which has a large heating area, high thermal efficiency, uniform heating, short liquid boiling time, and easy heating temperature. Control, beautiful appearance, easy installation, convenient operation, safe and reliable. The heating method of the pot body adopts the honeycomb structure design, and the heating utilization rate is higher than that of the old-fashioned halogen cooking equipment.

Advantages and characteristics of the stewed pot and the automatic intelligent stewed pipeline

1. The temperature control deviation of the whole pot is ±1℃, which fully guarantees the consistency of the taste of the whole pot.

2. The whole heating process is controlled by 53 setting procedures, which can fully ensure the consistency of the setting of heating and holding time and the product process.

3. The basket-carrying design of the material frame saves the process of turning over the product. The 24 standard material frames reduce the rate of product damage, facilitate the output of the pan, and save the time of turning the frame.

4. The boiling pot can be added with an automatic forced cooling system according to the customer's product technology to achieve forced cooling and heat preservation in the pot, increase product water retention, and improve product quality and taste.

5. It has its own heating and heat preservation and alarm system to avoid the product loss caused by the operator's forgetting.

6. The inner volume of the pot is 2500L, which can cook 720 500g grilled chicken, 450 1000g roast chicken, 600kg beef and 500kg pig's feet in one pot.

7. The brine boiling pot and the intelligent brine boiling transfer line are equipped with automatic stacking and unloading equipment, which does not require manual transfer, reducing labor intensity and work injury risks.

[Ruizhi Intelligence] Focus on quality for 20 years!

For product quality: we demand excellence!

For service: We always adhere to the customer-centric service concept and provide sincere, high-quality, and fast product services.

For after-sales: we share the burden for each customer with a sincere attitude!

简体中文

简体中文 English

English